In manufacturing today non-contact measurements are increasingly demanded with accuracy, speed and consistency. These measurements are typically performed on optical systems such as a comparators, traditional video measurement systems and/or a video measurement system that accommodates a large field of view. As you evaluate the requirements of your application to determine which style of optical system best fits your need, consider the following points.

Field of View (FOV)

The three primary factors that determine what is generally presents to the viewer/operator are optics (magnification), screen size (comparators), and sensor size (video). Traditional systems like comparators, in most cases have a small FOV while video measurement systems offer a large FOV option. If multiple measurements need to be taken within a single workpiece or the same measurement needs to be taken from multiple workpieces with little or no stage movement, a large FOV system would be your most efficient solution. The same measurements could be performed on a traditional system, however, they would likely require multiple stage movements and re-fixturing thus increasing the time required to perform the inspection.

Depth of Focus (DOF)

When your workpiece requires accurate measurements of multiple surfaces at varying heights, a large DOF should be considered. Once again, the more movement required by a system to obtain a measurement, the less efficient your inspection process will be from a time and throughput standpoint. Traditional systems like comparators typically have a shallow DOF and more often than not, require operators to re-focus the workpiece to obtain various measurements on varying surface heights.

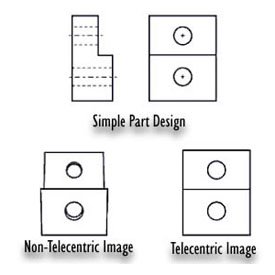

Telecentricity

Telecentricity allows an object to maintain consistent shape and size regardless of how far it is from the lens. In a system with a large DOF and telecentric optics, measurements will be consistent throughout the FOV whether they are taken in the center or edges of the stage. See the picture below for reference. Without telecentric optics, operators may be required to reposition the workpiece to measure specific features on different planes. Both traditional systems and large FOV systems offer options for accommodating Telecentricity. However, its worth noting that ensuring telecentricity is a critical factor to consider as you evaluate a large FOV systems.

Distortion

The optical characteristic of distortion allows an object to be accurately magnified while maintaining size and shape throughout the FOV. Optics with low distortion allow multiple features to be measured throughout the FOV while optics with high distortion require operators to move the features to the center of the FOV to obtain an accurate measurement.