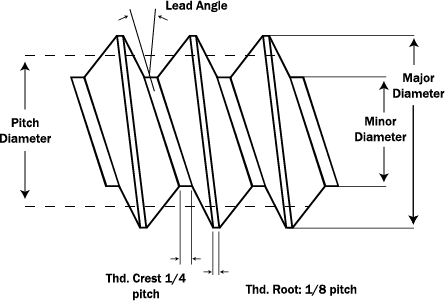

MAJOR DIAMETER – BASIC: All thread dimensions, internal and external are based on this dimension.

MINOR DIAMETER – ROOT: Must Clear the mating products minor diameter.

PITCH DIAMETER: Controls the fit of the mating parts, looseness, and tightness.

GO Thread Ring Gages

- Minus tolerance on ID (Inner or Minor Diameter_ and PO (Pitch Diameter)

- Functional check which checks the maximum pitch diameter, maximum minor diameter, flank angles, and lead.

- Engages for full length of thread free and easy.

NOGO, NOTGO, HI Thread Plug Gages

- Plus tolerance on ID (Inner or Minor Diameter) and PD (Pitch Diameter)

- Checks one feature only which is the minimum functional pitch diameter.

Inch: Acceptable when gage does not enter the product more than three complete turns. Thin or soft material, or a small number of threads may require altering three-turn limit. Per ANSI B1.2-1983

Metric: Acceptable when a definite drag from contact with the product material results on or before the second turn of entry. Per ANSI B1.16M-1984

PDF - External Thread Basics99.11 KB

SUBSCRIBE TO RECEIVE MORE OF OUR INSPECTION RELATED CONTENT